Modern Manufacturing Services

From concept through production, we work collaboratively with our customers to produce the optimum part.

Producing the optimum part means having the right set up. So, in 2022, we moved to a modern, 23,000 square-foot facility in the St. Louis, Missouri area, allowing us to expand our molding capabilities to include 85-to-500-ton presses and provide additional space for more presses, a quality lab, assembly, robotics automation and land for future expansion. Our facility also includes a central material handling system, additional equipment and robotics to improve production and changeover efficiency.

Close tolerance engineered plastic parts delivered with honesty, integrity and quality.

Injection Molding Services

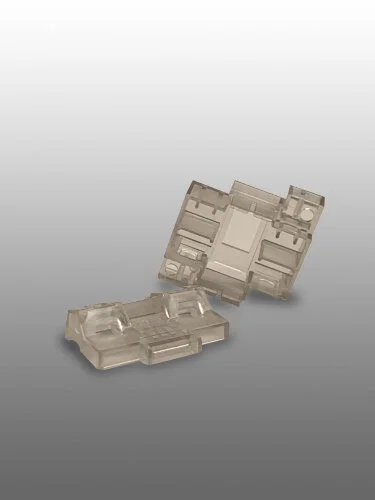

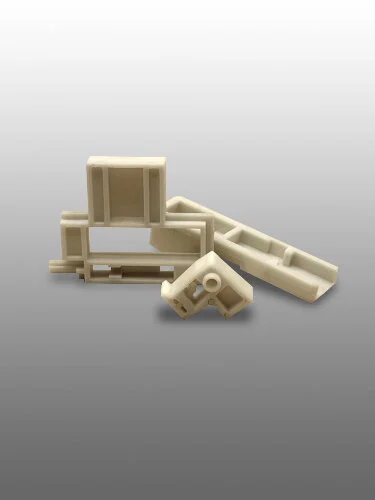

It all starts with the mold. We help customers create a tool based on use intent, moldability and reliability. Our process is efficient and focused on controlling tooling costs while delivering a finished product with minimal delays and rework. Depending on customer requirements, we have the ability to source the tool domestically or overseas.

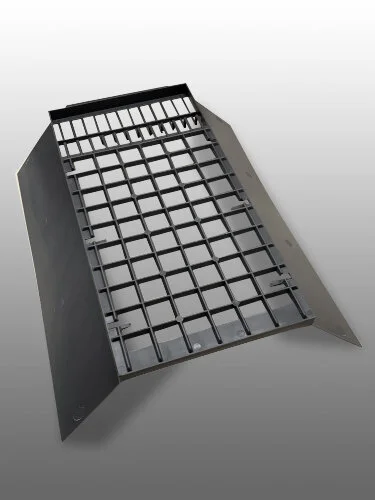

Our custom precision injection molding capabilities allow us to deliver short-, medium- and long-run plastic products across numerous industries. Our standardized process ensures quality while providing the flexibility to adjust to changes in production. We are not limited on materials we can mold – we work with nearly all engineering, commodity and specialty plastic materials.

Injection Molding Services Include:

Insert Molding

Over Molding

Hot Runner / Runnerless

Cold Runner Injection Molding

Custom Inventory Management

We take the burden of managing inventory off our customer’s shoulders. We analyze their data, identify trends and come up with a custom plan so they always have the right inventory in the right place and at the right time. Our programs help prevent product shortages in both raw materials and parts due to uncertainties in the supply chain. The result – we can efficiently, quickly and conveniently fulfill last-minute requests while simultaneously managing costs.

Production Capabilities

Our team can do so much more than just precision injection molding – from component sourcing through basic part assembly – you name it, we’ll do it. It’s just another way we take some of the weight off our customers’ shoulders.

Production capabilities include:

Component Sourcing

Prototyping

Part Assembly

Specialized Packaging

Sonic Welding

Adhesive/Solvent Bonding

Product Testing

Program Management

If you do not see a service that you need, just ask! We love a challenge.